We consider that subsequent era {hardware} manufacturing represents a seismic shift. We see from our personal shoppers and the businesses we work together with that sure particular developments are affecting the business. These developments are nearly common, however the timing is totally different throughout totally different sectors.

We see shorter product cycles, ‘smarter’ {hardware}’ shorter extra resilient provide chains and business and environmental sustainability as key drivers. Greater than this, we see that the following era of {hardware} isn’t simply sooner and extra linked, it’s really wanting extra like software program.

Extra and sooner is a part of the human situation, and so it’s that all through the evolution of producing we’ve strived for each. Right this moment the cascade of technological innovation is consistently accelerating the event of latest merchandise. As such they must be made extra shortly, are upgraded extra shortly and require in-use help long-after the OEM has moved on.

As we proceed to evolve Shapeways, we’re making a digital manufacturing ecosystem that retains tempo with the product improvement and offers all producers the power to make provide chains extra resilient.

Converging expectations

Since 2008 we’ve been in a position to work with everybody from first-time designers, hobbyists, small- and medium-scale producers by way of to blue chips and governments. From the outset what every of those teams was in search of was totally different, however they’ve additionally advanced alongside an identical path within the years since.

As with all expertise we’ve entry to for the primary time, the preliminary initiatives shall be comparatively decrease in worth, with fewer dangers. A roll of the cube. For us this was early mannequin making and prototyping relying on the shopper. These early use circumstances (that are nonetheless related) explored the geometric freedom of 3D printing, and made use of the power to shortly flip an concept into one thing tangible… if not the ‘actual factor’.

Over time every group has grow to be extra assured within the applied sciences and our capability to deploy them and requested for extra from their components in return. Hobbyists need finer particulars, color, supplies selections. Corporations need extra useful prototypes, even faster turnaround and entry to supplies and applied sciences that may understand end-use and more and more vital components. With that comes a plethora of different wants: traceability, repeatability, high quality management and expansive supplies palettes.

What makes subsequent era {hardware} totally different?

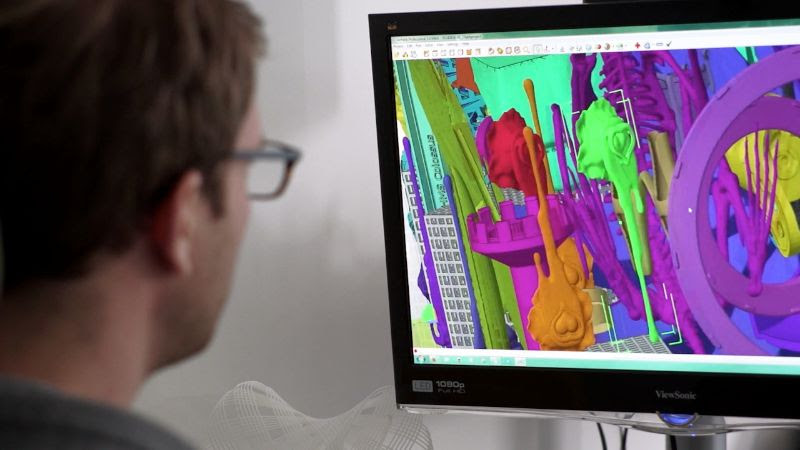

Each half exists now as knowledge factors earlier than it turns into bodily. Conventional manufacturing applied sciences and related provide chains and methods don’t all the time have the power to leverage that truth. Additive manufacturing because the core expertise of a digital manufacturing ecosystem can transfer extra responsively.

New {hardware} is smarter, leveraging fast developments in sensing and cell computing to hitch the ‘Web of issues’. It’s additionally extra more likely to have a definite software program element both onboard, by way of an app or each. And it will likely be out of date extra shortly because the built-in electronics components drive versioning.

A confluence of forces are driving this shift in {hardware} manufacturing:

- Provide chain issues — or the ‘dawning of a brand new provide chain period‘

- Software program-first product focus with {hardware} components second

- Startups seeking to get to market shortly, not arrange

- Tariffs and commerce limitations altering geographical considering

Constructing Shapeways for manufacturing subsequent era {hardware}

At Shapeways we’ve all the time believed that manufacturing must preserve tempo with product innovation, bus is simply too typically a brake. Because the world strikes towards a brand new era of {hardware}, we’ve targeted on constructing the infrastructure to make that potential: digital from the bottom up, agile by design and confirmed in manufacturing over many years.

Our platform connects design, manufacturing and supply in a single digital thread. Which means groups can transfer seamlessly from prototype to manufacturing with out rework, handoffs or hidden friction. A component designed as we speak could be manufactured tomorrow — regionally or globally — with the identical stage of high quality and management. Tomorrow possibly it’s time to scale that up, or down, or change to the following model.

We’ve spent greater than a decade refining the methods, supplies and partnerships that make this work at scale. From high-performance polymers and metals to carbon-fibre-reinforced supplies, our manufacturing community is constructed for velocity, repeatability and reliability. Each half is tracked, measured and verified. Each course of is designed to be as responsive as the businesses it serves.

For engineers, designers and product leaders we ship flexibility. The power to experiment, to provide what you want if you want it, and to belief that it’ll carry out as anticipated. For companies, it means manufacturing that may lastly transfer on the velocity of {hardware} improvement and the boldness to construct what comes subsequent.

Constructing for the following era of {hardware}

The shift is already underway. Yearly, the gap between concept and bodily product grows shorter. Essentially the most forward-thinking firms are now not asking if they will make one thing, however how shortly they will make it, validate it, and get it into clients’ fingers. That’s what the following era of {hardware} calls for: a producing mannequin that strikes on the velocity of design.

At Shapeways, we’re targeted on constructing the digital manufacturing infrastructure that allows that agility. One the place manufacturing knowledge, supplies science and supply-chain resilience work collectively as a single ecosystem. The place a component can transfer from CAD to manufacturing to international distribution with out the friction, waste or delay that used to outline bodily manufacturing.

{Hardware} will all the time be bodily — however the way it’s made is changing into more and more digital. The businesses that embrace that shift will lead the following era of merchandise, industries and concepts.

We’re right here to assist them make it actual.